Composite Manufacturing

AMEL specialises in processing advanced composites. We have vast experience in processing multiple material configurations for a wide variety of applications. Our expertise revolves around the intricate techniques involved in working with cutting-edge materials. From aerospace components to high-performance vehicle components, large scale models and marine components, we possess a deep understanding of the unique properties and challenges associated with advanced composites. With a focus on precision and innovation, we excel in crafting intricate structures that maximize strength-to-weight ratios, ensuring optimal performance in various industries. Our commitment lies in pushing the boundaries of composite technology, contributing to advancements that redefine the possibilities within this dynamic field.

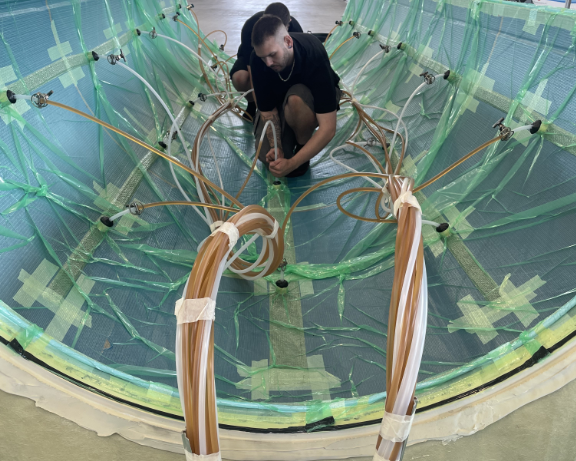

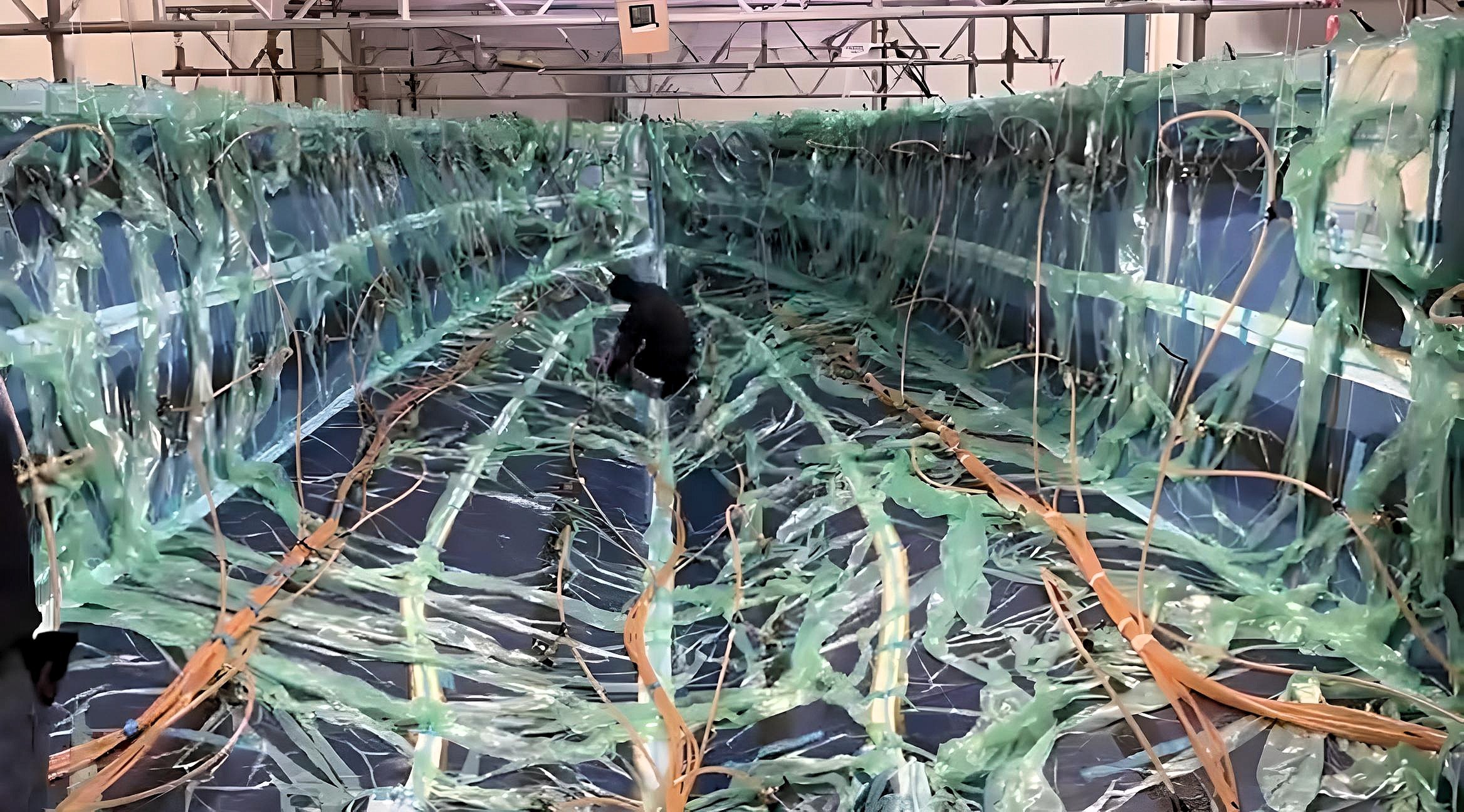

Resin Infusion

Vacuum resin infusion is a sophisticated technique for manufacturing high performance and void free composites. Dry reinforcement is laid into the mould, enclosed in a specially configured stack of bagging materials, and then subjected to vacuum pressure. Once the reinforcement has been fully compressed, liquid epoxy resin is added which infuses through the reinforcement under vacuum. When the resin has fully infused the resin is left to cure in the vacuum environment either at room temperature or in our oven.

Resign infusion produced parts are extremely strong, and have an impeccable appearance. They can be made with comparable fibre volume fractions to Pre-Preg and eliminate potential problems with air voids in traditional wet layup techniques.

Pre Preg Laminating

Fabric is placed into the mould and the layers are built up - a variety of materials can be used to make up a part including carbon, glass and amarid fibres. Other materials, such as foam can also be used to construct a thicker laminate whilst retaining the high strength and low weight benefits.

All the materials are placed in the mould which is packaged in a vacuum bag to aid the curing process. This is then placed inside our oven, where the part is cured.

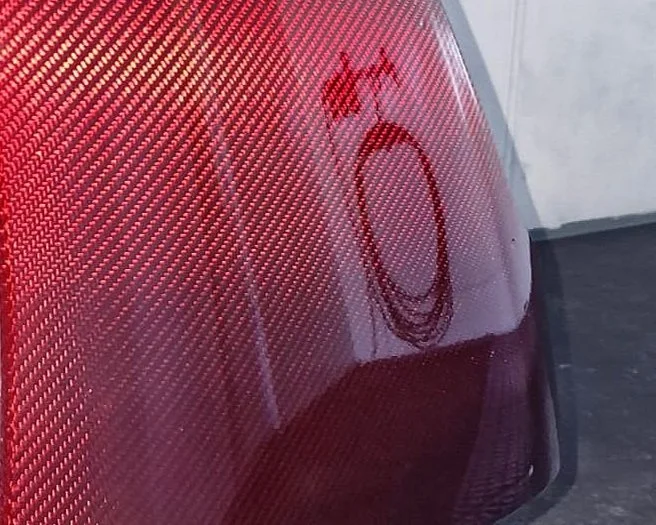

Composite Finishing

Specialising in composite finishing, painting, and vinyl wrapping, our expertise lies in transforming surfaces with precision and finesse. Whether it's enhancing the aesthetic appeal of composite materials, applying flawless paint finishes, or customising with vibrant vinyl wraps, our skilled team is dedicated to delivering high quality craftsmanship.